What Makes A Quality HVAC Installation?

It can be extremely overwhelming to try and choose between different HVAC companies when you’re looking to replace a system. Without insider knowledge of what all goes into an installation, it’s difficult to evaluate on anything but price and the impression you get when you talk to the salesperson or technician. The impression someone leaves on you is a big deal, and not a bad indicator of what your experience with the company will be like. But besides your intrapersonal interactions and the “vibe” you get from your conversation, I would like to offer 4 technical factors that lead to a quality HVAC installation.

An evaluation of your current system

Just because your previous HVAC system blew hot and cold air, doesn’t mean all is right with the world. Of course, you may know this already. If you’ve lived in your house for any length of time you can likely identify the hottest and coldest rooms in the house. A detailed evaluation of your current system will involve DATA NOT RULES OF THUMB. Many contractors size air conditioning equipment by square footage and ductwork by reading the duct sizes on the duct in the attic. This is extremely inaccurate and worthless in almost all cases. The size of an HVAC system should be sized by a load calculation using math, and a duct system can be evaluated in its current state with static pressure readings.

A load calculation is done in computer software, and I charge an additional fee for a detailed load calculation because it takes me several hours of time. I don’t perform a detailed load calculation on every home, but I will if enough red flags (such as high humidity, extreme comfort problems, very bad duct systems) come up.

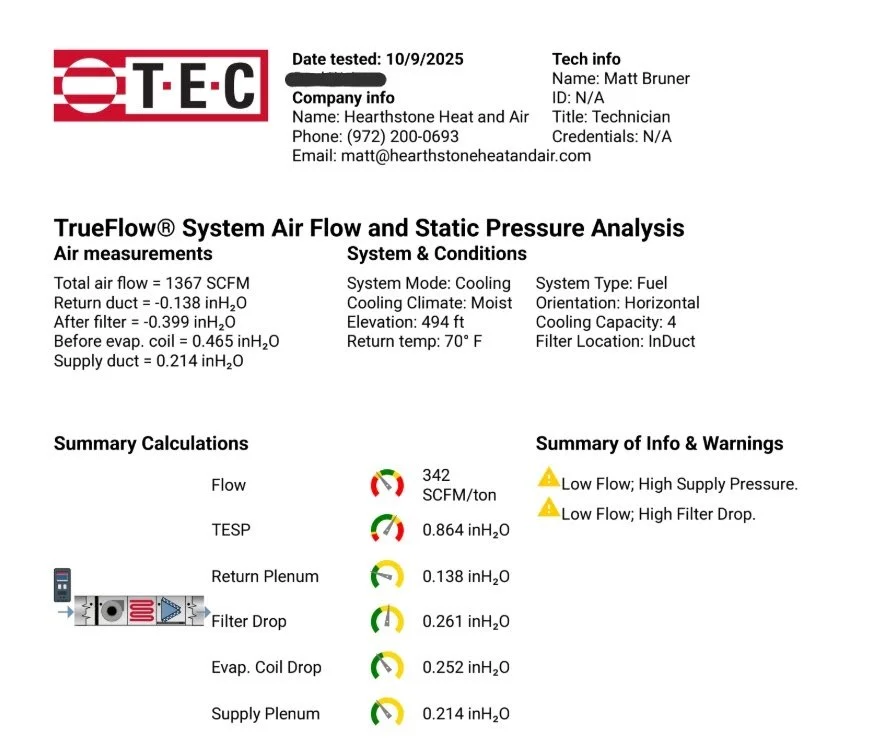

Static pressure testing (and a true flow grid measurement) is provided for free on every sales estimate I provide. Static pressure is simply a duct pressure reading taken while the system is on. A system will have a rated pressure, and you can compare your readings that you take to what the blower/fan in the system is rated for. This gives you a good sense of if the duct system can handle the airflow you are trying to move through it.

Undersized duct systems are incredibly common and are often the cause of comfort and noise problems, and premature fan motor failures. Below is a static pressure and airflow test I completed last year. Once the static pressure and airflow data is collected, informed decisions about how to alter the duct system can be made.

Flowing Nitrogen While Brazing

The picture above illustrates one of the most important things we can do when installing a new system, which is to purge the refrigerant lines with nitrogen while brazing. This is not a common practice, although it should be. In all my years of working for other companies it was never mandated or taught to me. I had to learn this process through watching Youtube videos.

If nitrogen is not used to displace the air inside the copper lines while brazing, soot builds up inside the pipe. The fancy name for it is cupric oxide. It doesn’t just look gross. Once refrigerant starts flowing through the pipes, it carries the soot around the system until it begins to clog up parts. This can result in component failures or decreased efficiency. It’s actually an easy process to learn to braze with nitrogen, and costs almost nothing extra.

Pulling A Deep Vacuum

Another process that is not well understood or followed is best vacuum practices. I won’t go too deep into the nitty gritty, but many companies and technicians simply don’t know how to pull a proper vacuum. Pulling a vacuum on an HVAC system means removing the air from the copper lines so that the only thing remaining in the system when it is running is refrigerant. If air is allowed to remain in the lines (even the tiniest amount!) it can mix with the refrigerant oil and break the oil down into acid. This acid begins to eat parts of the compressor and cause premature failures. For a deeper dive, check out this link.

Properly Commissioning on Startup

Once a system is turned in, it isn’t always ready to just get up and running. Refrigerant charge needs to be adjusted based on how far the indoor unit is from the outdoor unit, otherwise efficiency is lost. Airflow needs to be adjusted based on the exact model numbers of the equipment that is paired together, otherwise furnaces can overheat and AC units won’t dehumidify. If we are installing a furnace, we adjust gas pressure to the manufacturer’s settings and perform a combustion analysis. This ensures the system is dialed in as close to perfect as possible and running safely. All of these final steps can add a couple of hours to an install, but are critical in making sure you get what you paid for.

Closing Thoughts

Our goal in installing a new HVAC system is to guarantee that it runs as well as it can for as long as it can. I want to know that I did everything I could to provide you with the best HVAC install possible. There are factors that we cannot control, like part failures, power surges, or product recalls. But I want to do everything I can to make darn sure that your system runs safely and efficiently. I know that buying a new system is a huge investment. We follow these best practices because this is more than just a job to me. Even if we live far apart, I want to treat you like a neighbor. To me the steps above are a big part of what makes a quality, neighborly, HVAC installation.